SZ manufacturer Custom PEEK PBT PP Plastic parts plastic injection molding

PEEK (polyether ether ketone) is one of the most useful, versatile, and popular injection molding resins available. This unique, high-performance thermoplastic is ideal for medical applications because of its tolerance to gamma radiation exposure and sterilization processes such as autoclaving.

PEEK Injection Molding Properties, Characteristics And Applications

Properties & Characteristics Of PEEK Injection Molding. High temperature resistance: PEEK has a high glass transition temperature (Tg=143℃) and melting point (Tm=334℃), its load thermal deformation temperature is up to 316℃, long-term use temperature is 260℃, and instantaneous use temperature can reach 300 ℃.

How Does Plastic Injection Molding Work?

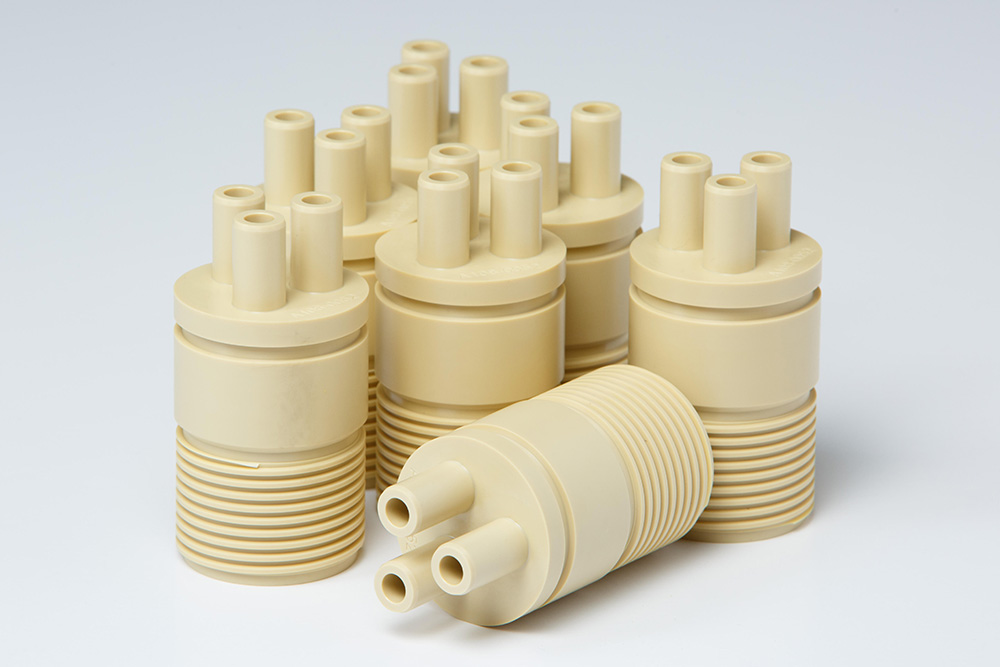

PEEK injection molding produces high-quality plastic parts from polyether ether ketone (PEEK), an engineering thermoplastic with applications in the medical and aerospace industries.

Fabricant de moulage par injection en plastique PEEKChine Connaissances Deep Mold Co., Ltd

Download Comparing Types of PEI Plastics At Protolabs, we stock four types of PEI: RTP 2100 LF, Ultem 2200, Ultem 1000, and Ultem 2300. All of these are suitable for injection molding, but only the last two are available to create machined parts. The materials' primary benefits are high heat resistance, impact resistance, and strength.

peek parts plastic injection molding YouTube

The introduction to PEEK plastic in injection molding opens the doors to a remarkable material renowned for its exceptional properties and versatility. PEEK, or Polyether Ether Ketone, stands as a high-performance thermoplastic that has captured the attention of industries ranging from aerospace to medical. Its distinct combination of.

Medical ABS/PC/PP/POM/PA/PE /Peek Plastic Injection Molding Parts Molded Plastic Products

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments. We bring transformational & sustainable solutions that address world material challenges every day.

plastic injection molding of PEEK

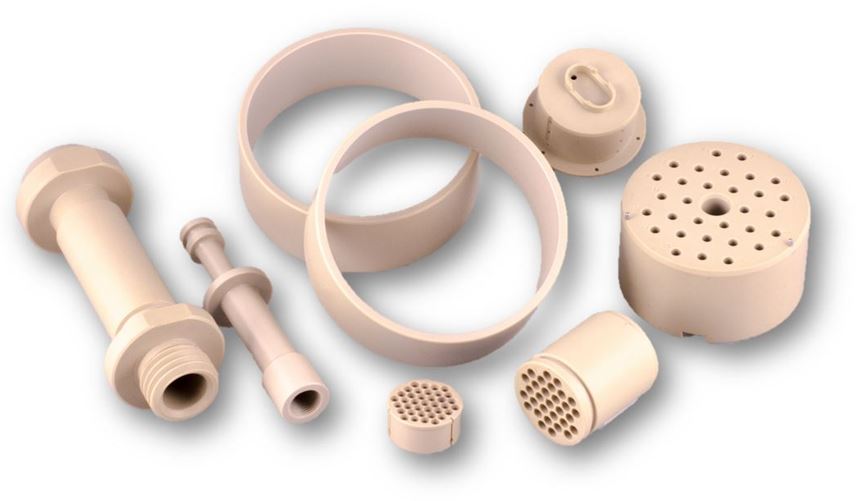

PEEK, or poly ether ketone, is a high performance thermoplastic with excellent strength and ductility. It's also FDA compliant for food contact and can be sterilized for medical applications. Key benefits Good strength and stiffness High ductility Chemically resistant Food safe PEEK Material Properties Molding Parameters PEEK Parts

peek plastic injection mould, peek plastic injection mould Suppliers and Manufacturers at

Polyetheretherketone (PEEK) is a high-strength, high-temperature thermoplastic with superior mechanical and chemical properties ideal for injection molding applications. About Polyetheretherketone (PEEK) replaces other materials, such as metals and composites, because of its stiffness and strength.

A Guide to PEEK Plastic in Injection Molding Xcentric Mold

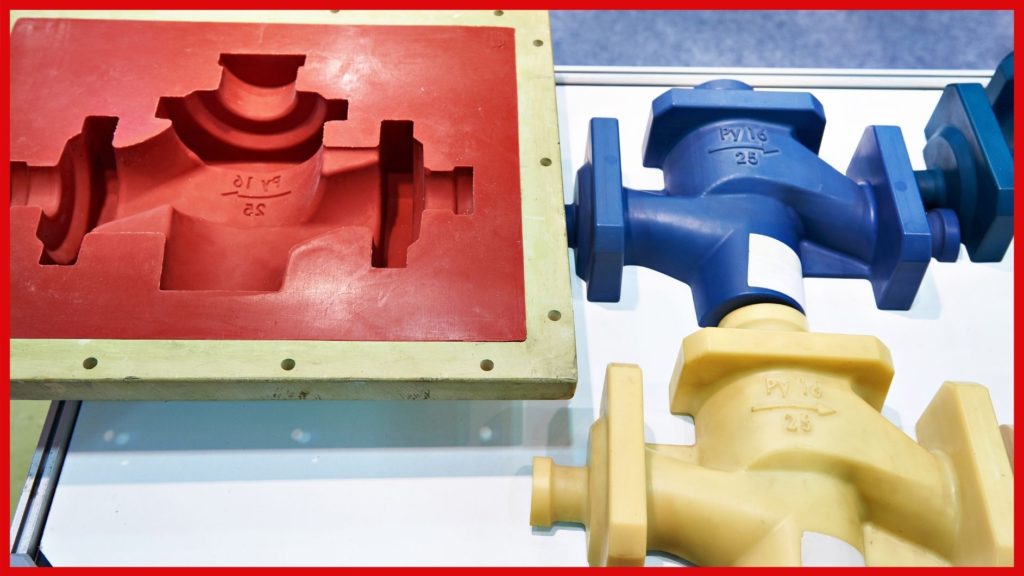

PEEK injection molding is a manufacturing process that involves melting pellets of polyetheretherketone (PEEK) resin and injecting the molten material into a mold cavity under high pressure.

The Top 39 Peek Injection Molding Manufacturers

A Guide to PEEK Plastic in Injection Molding - Xcentric Mold Rapid Manufacturing On-Demand | Xcentric Mold Find out more about PEEK plastic in injection molding and how to choose the best PEEK plastic for your needs.

PEEK Injection Molded Parts & Shapes

A Comprehensive Guide to Peek Plastic Injection Molding I. What is PEEK injection molding. PEEK (Polyetheretherketone) injection molding is a specialized manufacturing process that involves the production of intricate and high-performance components using PEEK thermoplastic material. PEEK is a high-performance engineering polymer known for its exceptional mechanical, thermal, and chemical.

PEEK Injection Molded Plastic is Taking the Place of Metal

PEEK, or polyetheretherketone is a semi-crystalline polymer and a high-performance engineering plastic. This material is biocompatible, has a high melting point (343°C), and has excellent mechanical properties. It is presently a popular research injection molding material.

Injection Molding Services, Thermoplastic and Rapid Injection Molding

#1 involves the equipment you use to mould PEEK. PEEK can be moulded on standard injection moulding machines supplied by most of the well-known machine suppliers. Depending on the grade of PEEK that you'll be moulding, processing temperatures on your injection moulding barrel will be somewhere in the range of 350-400⁰C.

SZ manufacturer Custom PEEK PBT PP Plastic parts plastic injection molding

PEEK plastic is a semicrystalline engineering thermoplastic of the polyaryletherketone (PAEK) family with high-temperature tolerances, strength, and stability across harsh environments. It is manufactured using stiff aromatic units, which contribute to its high melting point of 343 °C/649 °F.

PEEK Injection Molded Parts & Shapes

PEEK, or Polyether Ether Ketone, Peek Injection Molding is a sophisticated manufacturing process that involves the shaping of PEEK thermoplastic material into complex and intricate forms. PEEK is renowned for its exceptional mechanical, thermal, and chemical properties, making it an ideal candidate for a wide range of high-performance applications.

PEEK Injection Molding Plastic Tooling & Mold Making Service Online

PEEK can be molded on standard injection molding machines supplied by most of the well-known machine suppliers. Depending on the grade of PEEK that you'll be molding, processing temperatures on your injection molding barrel will be somewhere in the range of 350°C-400°C (662°F-752°F).